Ball Clay

Supplier in India

Puresil India is a trusted ball clay supplier, providing high-quality ball clay for ceramic and refractory industries that demand superior plasticity, strength, and consistency. Our ball clay is carefully mined and processed to deliver excellent workability, reliable firing behavior, and uniform performance across batches.

With extensive reserves and strict quality control, we ensure long-term supply reliability for manufacturers in India and global markets.

What is ball clay?

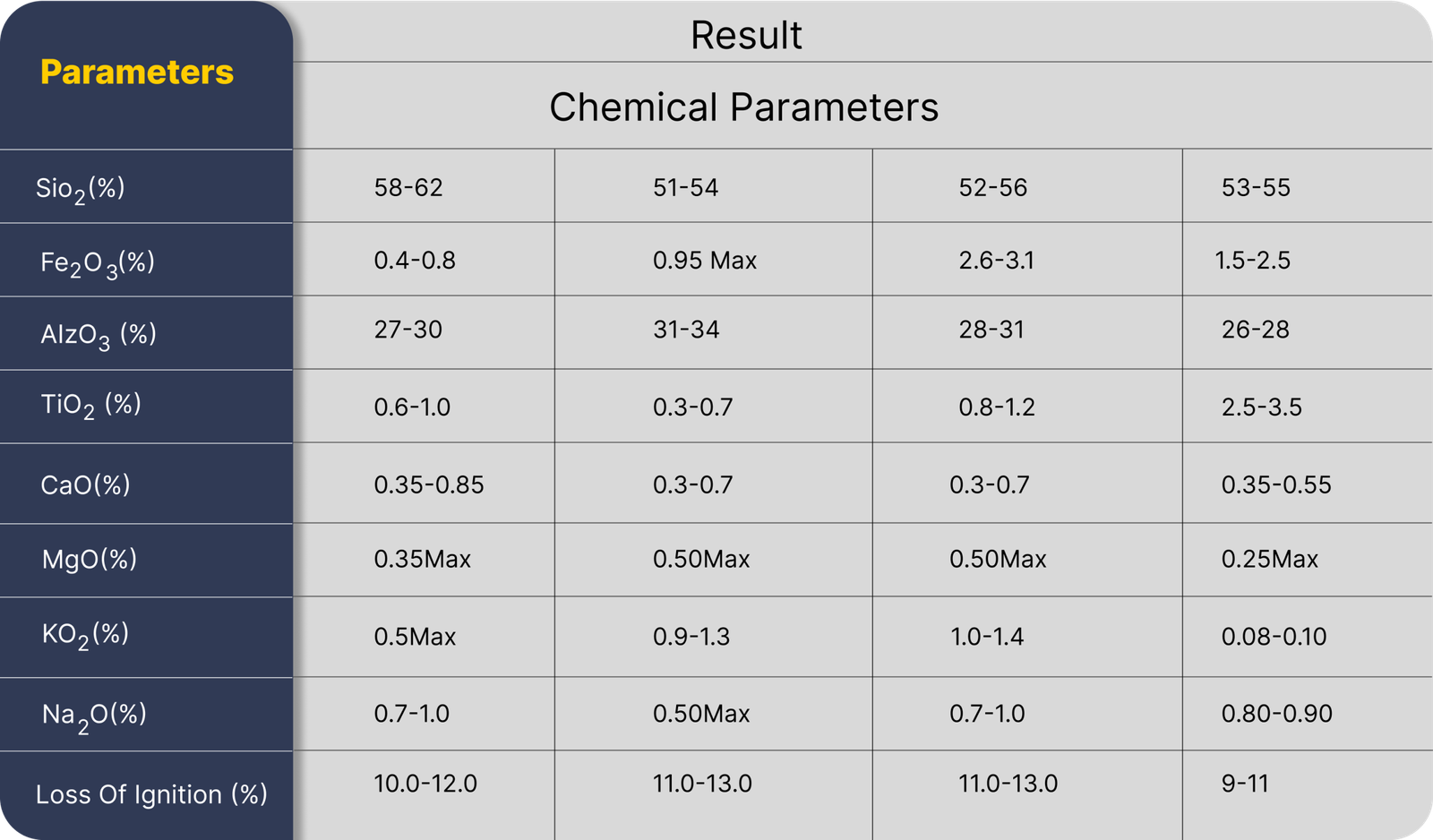

Ball clay is a highly plastic, fine-grained sedimentary clay known for its exceptional bonding strength and workability. It primarily consists of kaolinite (20–80%), along with mica and quartz. This natural composition gives ball clay excellent plasticity, smooth shaping ability, and high dry strength.

Due to these properties, ball clay plays a vital role in ceramic formulations where shape retention, surface finish, and firing performance are critical.

Why Choose Puresil India for Ball Clay?

- Extensive Mineral Reserves: Millions of tons of premium-quality ball clay ensure uninterrupted long-term supply

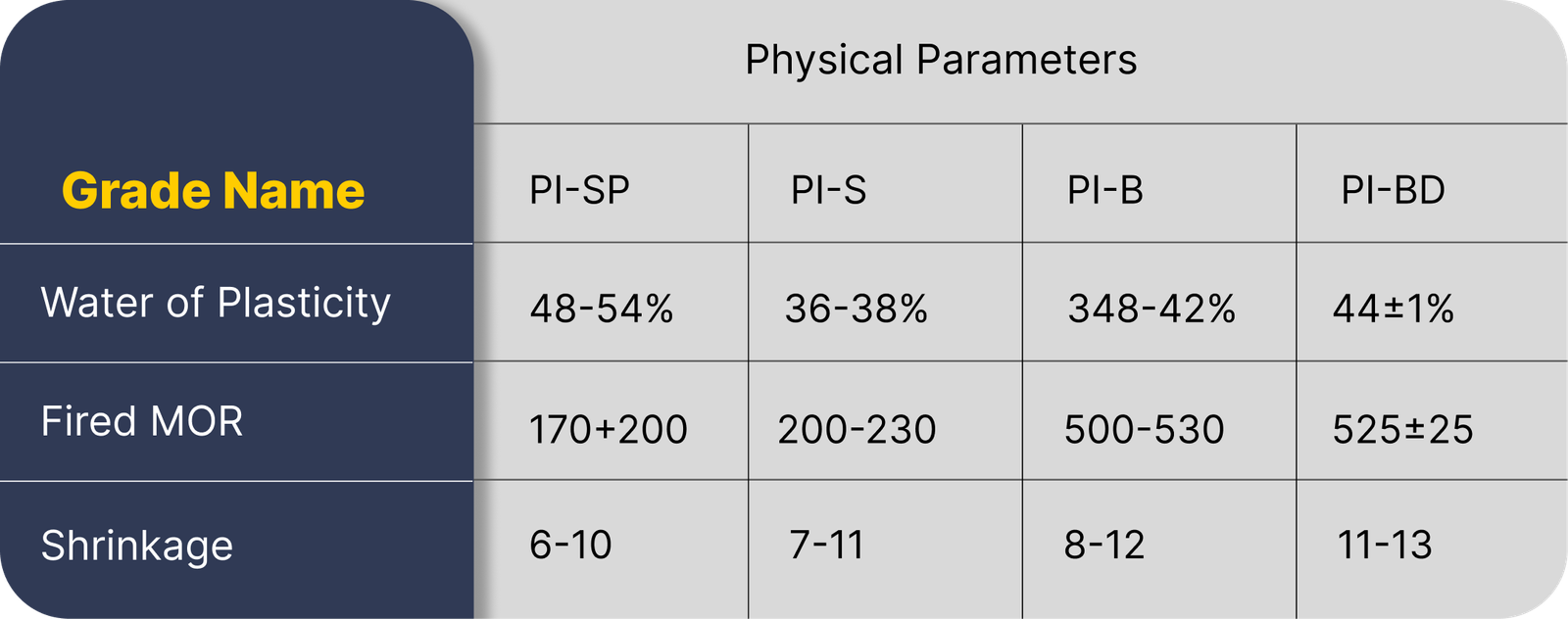

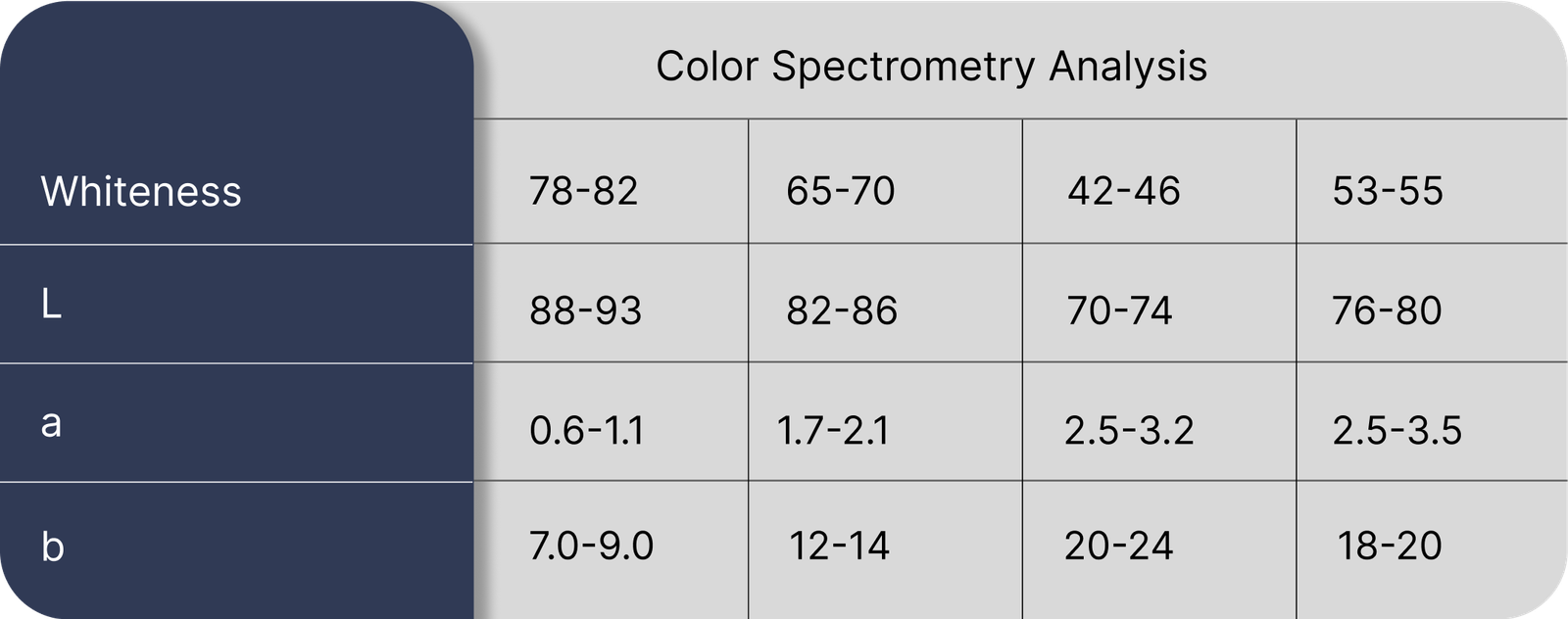

- Customized Grade Selection: Grades tailored based on fired colour, L-value, shrinkage, and ceramic performance requirements

- Advanced In-House Laboratory: Strict testing for plasticity, mineral composition, and firing behaviour

- Strategic Export Advantage: Proximity to Kandla and Mundra ports enables efficient global logistics

- Trusted by Ceramic Manufacturers: Known for consistent quality, timely dispatch, and customer satisfaction

Technical

Advantages

- White to Off-White Fired Colour: Delivers a clean, aesthetic finish—ideal for high-end ceramic and sanitaryware applications

- Exceptional Plasticity: Enables easy shaping, molding, and forming, supporting complex designs and precision manufacturing

- High Dry Strength: Maintains structural integrity during drying and handling, reducing defects and improving yield

- Fine Particle Size: Provides smooth surface finishes and excellent casting behavior, enhancing product quality

- Enhanced Vitrification: Promotes dense, non-porous ceramic bodies upon firing, improving durability and water resistance

- Cost-Effective & Widely Available: Offers excellent value compared to alternative minerals, with reliable supply from abundant reserves

Applications and Uses of Ball Clay

Used as a key body material for shaping, plasticity, and strength in forming and firing processes

Acts as a functional filler to improve flow characteristics, texture, and dimensional stability

Enhances body and adhesion properties as a filler, contributing to consistency and bonding strength

Serves as a filler to improve viscosity, opacity, and surface smoothness

Adds workability and aids in shaping during production, improving handling and finish quality

Key Benefits

Exceptional Plasticity

Allows easy shaping, molding, and forming

High Dry (Green) Strength

Reduces breakage during drying and handling

White to Off-White Fired Colour

Ideal for high-quality ceramic and sanitaryware products

Fine Particle Size

Ensures smooth surfaces and uniform texture

Enhanced Vitrification

Produces dense, low-porosity ceramic bodies after firing

Cost-Effective Solution

Reliable performance with economical sourcing

Explore our other

industrial products

Global Supply & Export Capability

As a reliable ball clay exporter, Puresil India supplies consistent-quality ball clay to customers across India and international markets. Our strong logistics network and export-oriented infrastructure ensure timely delivery, stable supply, and competitive pricing for large-scale manufacturers.

Ready to order

high-purity Ball Clay

?

Frequently Ask

Questions

Ball clay is a fine‑grained, naturally occurring clay mineral known for its plasticity, workability, and binding properties. It is widely used in various industrial applications where moldability and strength are required.

Ball clay is commonly used in industries such as:

- Ceramics and tile manufacturing

- Sanitaryware and dinnerware production

- Refractories

- Reno products and specialty ceramics

Its plastic and bonding properties support shaping and firing processes in these applications.

No. Ball clay and kaolin clay are both clay minerals but differ in properties:

Ball clay is highly plastic and workable, ideal for shaping and molding.

Kaolin clay has higher purity and whiteness, valued for surface properties and thermal stability.

They are used for different manufacturing purposes.

Yes. Ball clay is widely used in industrial manufacturing processes that involve molding, shaping, and firing, especially in the ceramics industry.

India has multiple ball clay suppliers. Puresil is among the companies that supply processed ball clay suitable for industrial applications.

Yes. Ball clay can be processed and graded to meet different application needs based on industry requirements.