Calcined Kaolin

Manufacturer in India

Puresil India is among the trusted calcined kaolin manufacturers, producing high-quality calcined kaolin designed for demanding industrial applications. Using controlled thermal processing, we transform high-grade natural kaolin into a non-hydrated, amorphous alumino-silicate with enhanced whiteness, hardness, opacity, and thermal stability.

With strong reserves, advanced processing facilities, and reliable logistics, we supply calcined kaolin to customers seeking consistent quality and long-term supply assurance.

What is calcined kaolin

Calcined kaolin is produced by heating refined kaolin clay at temperatures ranging from 900°C to 1100°C. This calcination process removes structural water and alters the mineral structure, resulting in a material with improved optical, mechanical, and insulating properties.

Compared to raw kaolin, calcined kaolin offers higher brightness, better opacity, lower loss on ignition, and improved performance in high-temperature and high-specification industrial environments.

Why Choose Puresil India for Calcined Kaolin?

Puresil India stands out as a reliable calcined kaolin supplier due to our focus on quality, consistency, and industrial performance.

Abundant Reserves: Millions of tons of high-grade kaolin ensure long-term supply stability

Tailored Calcined Grades: Custom grades based on brightness, particle size, and application needs

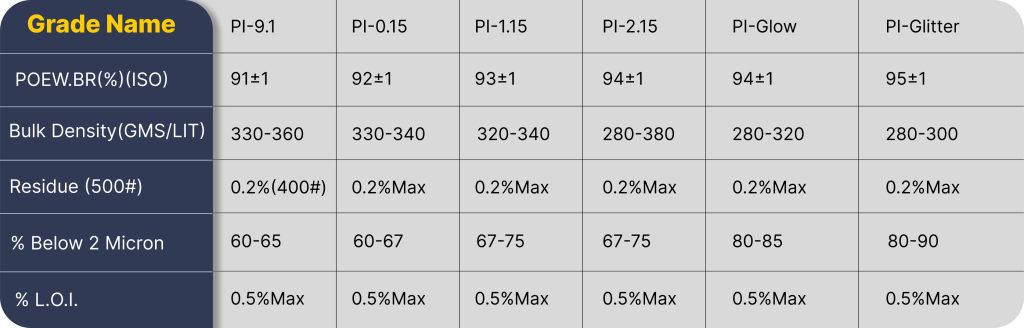

Exceptional Brightness: ISO brightness levels exceeding 90–95%

Ultra-Fine Particle Sizes: Specialized grades with particle sizes below 2 microns

Low Loss on Ignition (LOI): Ensures stability in heat-sensitive applications

Consistent Bulk Density: Supports predictable blending, handling, and logistics

Export Advantage: Strategic proximity to Kandla and Mundra ports for efficient global shipping

- Proven Reliability: Consistent quality, timely dispatch, and strong customer trust

Technical

Advantages

- Exceptional Brightness: ISO brightness levels exceeding 90–95% deliver superior optical properties for high-performance applications

- Ultra-Fine Particle Distribution: 2-micron particle sizes ensure smooth surface finishes, excellent dispersion, and enhanced opacity

- Low Loss on Ignition (LOI): Thermal stability with minimal LOI reduces interference in heat-sensitive processes and improves formulation reliability

- Consistent Bulk Density: Uniform density supports efficient handling, precise blending, predictable shipping weights, and cost control

Applications of Calcined Kaolin

As a raw material for glaze application

Used as a matting agent and TiO₂ extender

Used as coating agent for high gloss paper

Used as functional filler

Used in low-smoke, zero-halogen cable insulation materials

Provides stiffness and thixotropy

Key Benefits of Our Calcined Kaolin

Superior Whiteness & Opacity

Enhances visual quality and product appearance

Ultra-Fine Particle Distribution

Ensures smooth finishes and uniform dispersion

Thermal Stability

Performs reliably under high-temperature conditions

Low LOI

Reduces formulation interference and improves process control

Consistent Performance

Uniform quality across batches

Trusted Supply

Backed by experienced Calcined Kaolin Manufacturers and exporters

Explore our other

industrial products

Global Reach & Export Capability

As an experienced calcined kaolin exporter, Puresil India supplies high-quality calcined kaolin to domestic and international markets. Our strong logistics network and export-oriented infrastructure ensure timely delivery and consistent supply for global customers.

Ready to order

high-purity Calcined Kaolin

?

Frequently Ask

Questions

Calcined kaolin is a processed form of kaolin clay that has been heated at high temperatures to remove water and change its physical properties. This increases its brightness, hardness, and performance for manufacturing and industrial uses.

Yes. Puresil India is one of the companies that manufacture calcined kaolin suited for industrial and commercial applications, providing processed material that meets standard performance needs.

Yes. Puresil India supplies calcined kaolin to customers based on application requirements and industry specifications, with delivery options for domestic and international industries.

Calcined kaolin is typically supplied in bulk packaging or bags depending on quantity and customer requirements. Supply terms vary based on order size and destination.

Yes. Calcined kaolin is commonly used as a functional filler in rubber, plastics, and adhesives where strength, consistency, and stability are required.