Feldspar

Supplier in India

Puresil India is a trusted Feldspar Supplier, offering high-purity feldspar that meets the strict requirements of industrial applications. Known for its fluxing properties, low iron content, and fine particle size, our feldspar enhances mechanical strength, durability, and surface finish across ceramics, glass, and other industrial processes.

With extensive reserves and advanced processing capabilities, we provide consistent quality and reliable supply for both domestic and international customers seeking high-performance feldspar.

What is feldspar ?

Feldspar is a naturally occurring aluminosilicate mineral widely used in industrial applications. It acts as a fluxing agent in ceramic and glass manufacturing, reducing the melting temperature of mixtures and improving the mechanical strength, durability, and surface smoothness of finished products.

Feldspar is available in two main types: potassium feldspar and sodium feldspar, supplied in lump and powder forms to meet diverse industrial needs.

Why Choose Puresil India for Silica Sand?

- Extensive Reserves: Millions of tons of premium-grade feldspar ensure long-term supply stability

- Diverse Grade Options: Potassium and Sodium feldspar, available in lump and powder forms

- Application-Specific Customization: Tailored grades for ceramics, glass, and other industries

- Advanced In-House Laboratory: Rigorous quality control for consistent composition, purity, and performance

- Strategic Export Advantage: Close to Kandla and Mundra ports for efficient global shipping

- Trusted by Clients Worldwide: Proven track record of consistent quality and timely dispatch

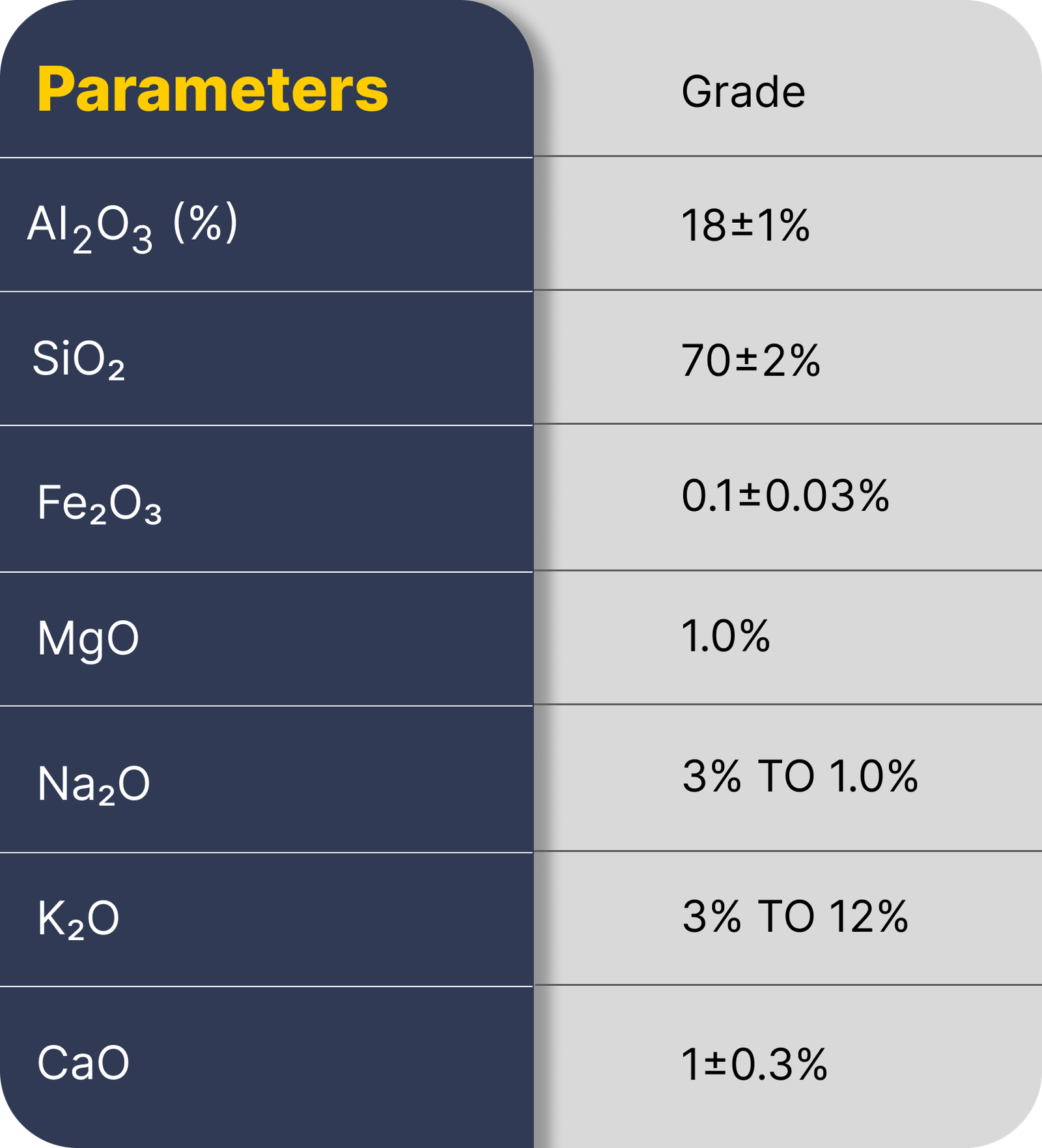

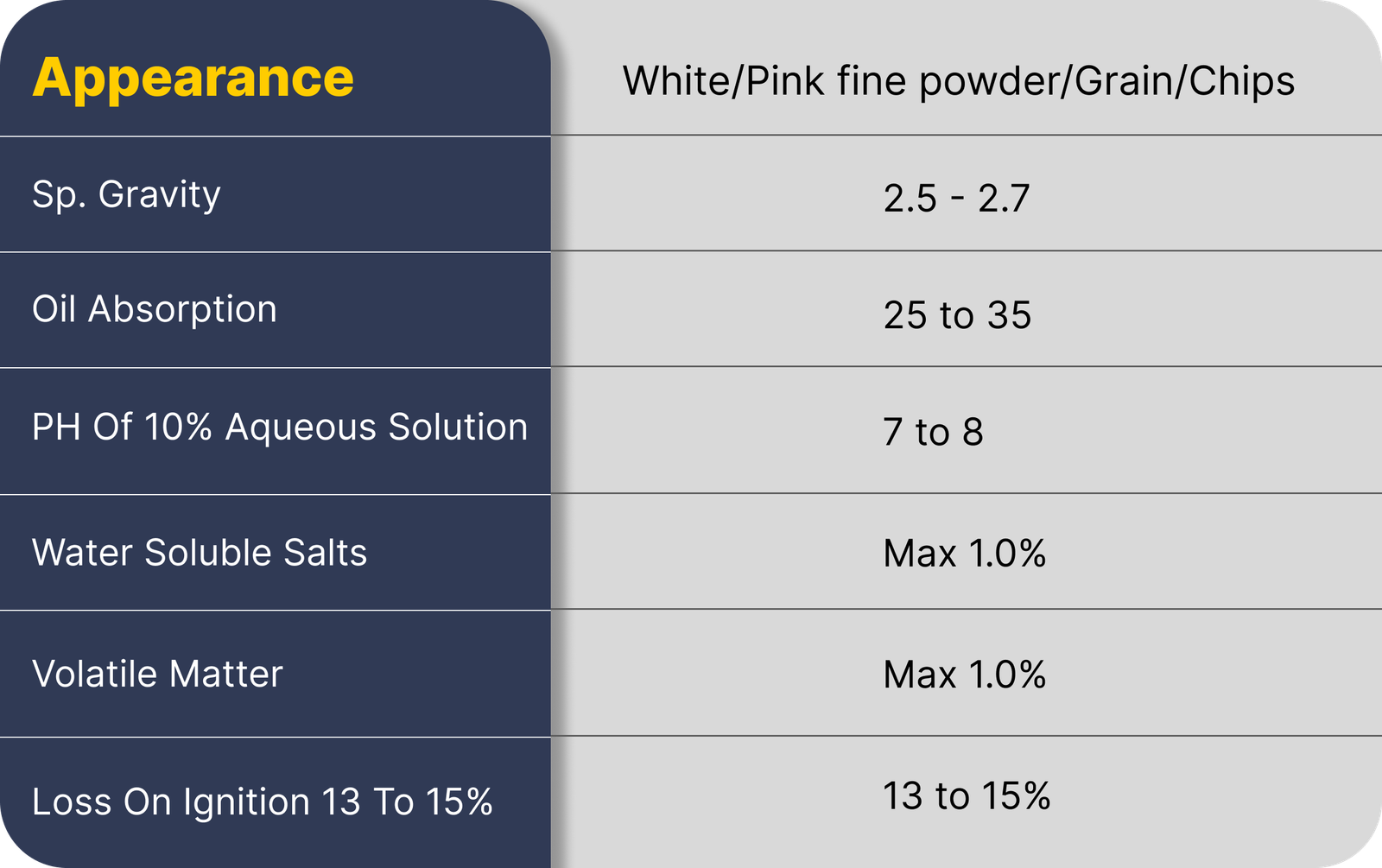

Technical

Advantages

- Fine Particle Size: Promotes uniformity in ceramic glazes and paint formulations, enhancing surface smoothness and finish quality

- Low Iron Content: Enables the production of clear or light-coloured glass by minimizing discoloration and improving optical clarity

- Enhanced Strength Post-Firing: Contributes to improved mechanical strength and durability in fired ceramic products

- Cost-Effective Mineral Solution: Abundant availability makes feldspar a budget-friendly alternative to other industrial minerals

- Environmentally Friendly: Non-toxic and more sustainable compared to synthetic additives, supporting eco-conscious manufacturing

- Consistent Bulk Density: Ensures predictable handling, blending, and shipping—critical for process efficiency and cost control

Applications and Uses of Feldspar

Lowers melting point, improves optical clarity, and reduces defects

Low iron content ensures maximum transparency and efficiency

Enhances strength, durability, and glaze uniformity

Promotes smooth surface finish and consistent color

Reinforcement for composites, insulation, and construction materials

Supports reliable chemical reactions with high-purity silica

Optimizes mold precision and casting quality

Enhances concrete, fillers, and industrial materials

Key Benefits

Improved Mechanical Strength

Enhances the durability of finished products

Low Iron Content

Produces clear or light-colored glass with minimal discoloration

Fine Particle Size

Ensures smooth surface finish and uniform blending

Thermally Stable

Performs reliably in high-temperature applications

Cost-Effective Mineral

Abundant availability reduces overall production cost

Eco-Friendly

Non-toxic and sustainable alternative to synthetic additives

Explore our other

industrial products

Global Reach & Export Capability

As a trusted feldspar manufacturer and exporter, Puresil India supplies high-quality feldspar to domestic and international markets. With strong logistics and strategic port proximity, we ensure timely delivery, consistent quality, and reliable supply for all customers seeking feldspar for industrial use.

Ready to order

high-purity Feldspar

?

Frequently Ask

Questions

Feldspar is a group of naturally occurring rock-forming minerals composed mainly of aluminum silicates of potassium, sodium, and calcium. Feldspar minerals are widely used in industrial applications such as ceramics, glass, and manufacturing due to their fluxing properties and high melting points.

Feldspar does not have a single chemical formula because it includes several related minerals. Common feldspar formulas include:

- KAlSi₃O₈ (potassium feldspar)

- NaAlSi₃O₈ (sodium feldspar)

- CaAl₂Si₂O₈ (calcium feldspar)

These represent the main feldspar mineral compositions.

The main types of feldspar are:

- Potassium Feldspar (K-Feldspar)

- Sodium Feldspar (Na-Feldspar)

- Calcium Feldspar (Plagioclase Feldspar)

These feldspar types are classified based on their chemical composition and are widely used in industrial manufacturing.

Feldspar is commonly used across multiple industries due to its role as a flux and performance enhancer. Major applications include:

- Ceramics & Tiles - Improves strength, durability, and surface finish

- Glass Manufacturing - Enhances transparency and melting efficiency

- Sanitaryware - Provides smooth texture and structural stability

- Paints & Coatings - Acts as a functional filler

- Plastics & Rubber - Improves rigidity and thermal resistance

Feldspar is widely used in industrial manufacturing when handled according to standard safety practices. Appropriate dust control and handling measures are recommended during processing and use.

Feldspar is typically supplied in bulk or packaged form based on order requirements. Supply depends on quantity, industry usage, and logistics.

Feldspar is processed through crushing, grinding, washing, and quality testing to achieve the required purity, particle size, and consistency for industrial applications.