Refractory Clay

Supplier in India

Puresil India is a reliable refractory clay supplier, providing high-quality refractory clay for industries operating under extreme temperature conditions. Known for its thermal stability, high alumina content, and resistance to chemical attack, our refractory clay delivers consistent performance in high-heat industrial environments.

With extensive reserves and controlled processing, we support manufacturers who require durable, cost-effective, and dependable refractory raw materials.

What is Refractory Clay ?

Refractory clay, commonly referred to as fire clay, is a naturally occurring mineral designed to withstand very high temperatures without deforming, softening, or melting. Its composition, rich in alumina and silica, allows it to maintain structural integrity under intense heat and thermal shock.

Due to these properties, refractory clay is widely used in the manufacturing of heat-resistant linings and refractory products for industrial furnaces and kilns.

Why Choose Puresil India for Refractory Clay?

- Extensive Mineral Reserves: Millions of tons of premium-quality refractory clay ensure uninterrupted supply

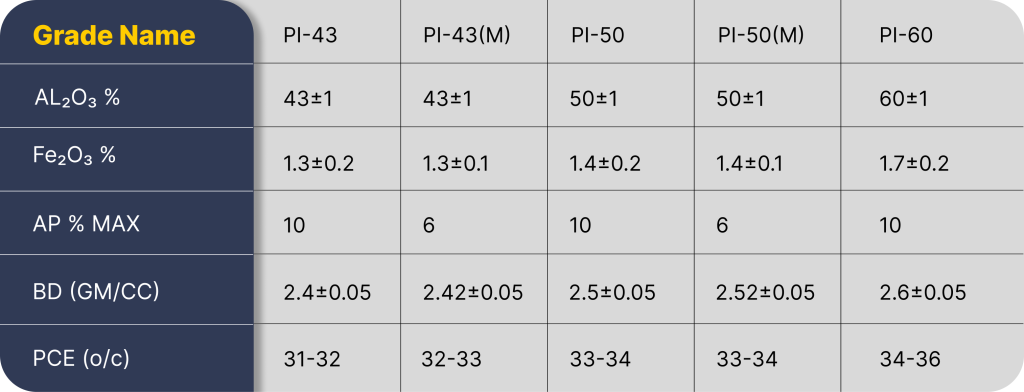

- Custom Grade Specifications: Grades tailored for alumina content, low iron levels, and application-specific performance

- Advanced In-House Laboratory: Strict testing for chemical composition, thermal stability, and reliability

- Strategic Export Advantage: Proximity to Kandla and Mundra ports enables efficient global logistics

- Trusted Industry Partner: Known for consistent quality, customer satisfaction, and timely dispatch

Technical

Advantages

- High Thermal Resistance: Withstands extreme temperatures, making it ideal for furnaces, kilns, incinerators, and reactors

- Superior Thermal Insulation: Retains heat within systems, minimizes energy loss, and enhances overall thermal efficiency

- Chemical Resistance: Durable against attack from slags, fluxes, and corrosive gases—both acidic and basic—ensuring long-term performance

- Cost-Effective Solution: Widely available and competitively priced, offering excellent value compared to alternative refractory minerals

- Environmentally Friendly: Non-toxic and more sustainable than synthetic additives, supporting eco-conscious manufacturing

- Consistent Bulk Density: Enables predictable handling, blending, and shipping—critical for process control and cost optimization

Applications and Uses of Refractory Clay

Serves as a key raw material in the production of heat-resistant bricks for furnaces, kilns, and incinerators

Used as a raw material in formulating mortar for joining refractory bricks, ensuring thermal stability and adhesion under extreme temperatures

Integral to castable refractory formulations, providing structural integrity and thermal resistance for monolithic linings and repair systems

Explore our other

industrial products

Global Supply & Export Capability

As a trusted refractory clay exporter, Puresil India supplies high-quality refractory clay to customers across India and international markets. Our strong logistics network ensures consistent supply, competitive pricing, and timely delivery for industrial-scale operations.

Ready to order

high-purity Refractory Clay

?

Frequently Ask

Questions

Refractory clay is a type of clay mineral that can withstand high temperatures and is used in manufacturing heat-resistant products such as firebricks and other refractory materials.

Yes. Refractory clay is specifically valued because it maintains structural integrity and stability at elevated temperatures where ordinary clays cannot.

There are several companies in India involved in mining and processing refractory clay. Puresil India is among the manufacturers supplying refractory clay for industrial use.

Yes. Refractory clay can be processed and graded to meet different industrial application requirements, depending on performance needs.

Yes, Puresil exports refractory clay to multiple international markets, ensuring consistent quality, proper documentation, and reliable supply for global customers.

"Yes! Simply reach out via our contact form https://puresil.in/contact-us/ or email at info@puresil.in

Provide your required quantity and application, and our team will provide a customized quote."