Silica Sand

Manufacturer in India

Puresil India is the nation’s leading silica sand manufacturer, producing over 800,000 tons of high-purity silica sand annually. Leveraging advanced mining, crushing, washing, and refining techniques, combined with technology from India, China, Italy, Germany, and Australia, we deliver consistent quality, purity, and performance for industrial applications.

What is Silica Sand?

Silica sand is a naturally occurring mineral primarily composed of SiO₂ (silicon dioxide). Extracted from high-grade quartz deposits, it is processed to remove impurities, resulting in a mineral with chemical stability, hardness, and thermal resistance.

High-purity pure silica sand is essential for industries requiring durability, transparency, and heat resistance. Buyers looking to buy silica sand rely on consistent quality for optimal industrial performance.

Why Choose Puresil India for Silica Sand?

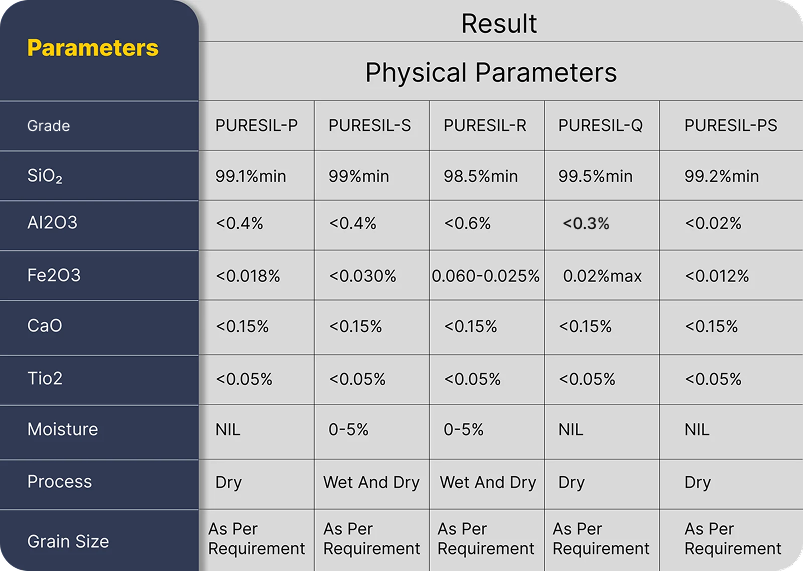

Puresil India’s silica sand stands out due to:

- High Purity: SiO₂ content exceeding 99% for superior industrial performance

- Ultra-Low Iron Content: Ideal for solar glass and high-transparency glass applications

- Consistent Particle Size: Uniform granulometry ensures smooth processing

- Thermal & Chemical Stability: Reliable performance under demanding conditions

Large Production Capacity: 800,000 tons annually ensures bulk supply

Vertical Plant Advantage: India’s first vertical silica sand plant with the largest grinding facility

Custom Grades Available: Tailored solutions for specific industrial needs

In-House Laboratories: Continuous testing guarantees consistency and reliability

Technical

Advantages

- High Purity: SiO₂ content exceeding 99%

- Ultra-Low Iron: Fe₂O₃ levels ideal for solar and high-transparency glass

- Consistent Granulometry: Uniform particle size distribution

- Thermal Excellence: Superior stability and refractoriness for demanding applications

Applications of Silica Sand

Enhances clarity, reduces defects, strengthens glass

Low iron content ensures maximum transparency and efficiency

Improves durability, finish, and brightness

Provides smooth texture and uniform color coverage

Reinforcement for composites, insulation, and construction materials

Supports reliable chemical reactions with high-purity silica

Optimizes mold precision and casting quality

Enhances concrete, fillers, and industrial materials

Key Benefits

Superior Product Quality

High-purity pure silica sand improves industrial performance

Consistency

Uniform particle size ensures fewer defects and smooth processing

Efficiency

Low iron content enhances transparency in solar panels and glass

Durability

Thermal and chemical stability ensures longevity in demanding applications

Custom Solutions

Tailored grades and mesh sizes to meet industrial needs

Reliable Supply

Trusted Industrial Minerals Suppliers ensure consistent availability when you buy silica sand

Explore our other

industrial products

Global Reach & Supply Capability

Ready to order

high-purity Silica Sand?

Frequently Ask

Questions

Silica sand is a naturally occurring material mainly composed of silicon dioxide (SiO₂). It is obtained from quartz-rich deposits and is widely used in industrial and manufacturing applications.

The chemical formula of silica sand is SiO₂ (Silicon Dioxide).

Silica sand is used across multiple industries, including:

- Glass manufacturing

- Foundry casting

- Ceramics & tiles

- Sandblasting

- Construction

- Fiberglass

- Solar glass

- Paints, coatings, and chemicals

The HSN code for silica sand is 250510, which is used for trade, taxation, and export purposes in India.

Silica sand prices in India depend on purity, grain size, moisture content, and application. For accurate and bulk pricing, it is best to contact Puresil India, a trusted silica sand manufacturer and exporter.

Silica sand at Puresil India is processed using:

Washing & hydrocycloning

Screening & grading

Magnetic separation

Quality testing for purity and grain size

This ensures high-performance industrial silica sand.

You can contact Puresil India via the Contact Us page on the website or email info@puresil.in for bulk orders, technical specifications, and export inquiries.