Kaolin Clay: Unlocking Opportunities in the Egyptian Market with Puresil India

Egypt, a land of ancient civilization and modern industry, offers vast potential for raw materials that drive its economic growth. Among these materials, kaolin clay has emerged as a cornerstone for multiple industries, from ceramics to paper, paints, and rubber. At Puresil India, we are excited to bring our premium-grade kaolin clay to the Egyptian market, ensuring industries benefit from unparalleled quality and consistent supply.

Why Kaolin Clay?

Kaolin clay, also known as china clay, is a naturally occurring mineral with exceptional properties, including:

- High Purity and Whiteness: Ideal for ceramics and high-end applications.

- Fine Particle Size: Enhances surface smoothness in paints and coatings.

- Thermal and Chemical Stability: Makes it indispensable in rubber, plastics, and refractory products.

- Excellent Binding Properties: Ensures durability and efficiency in paper and adhesives.

These properties make kaolin clay a versatile and valuable input for a variety of industrial processes in Egypt.

Industries in Egypt Leveraging Kaolin Clay

- Ceramics and Porcelain:

Egypt has a rich tradition of ceramics production, from decorative tiles to porcelain ware. Kaolin clay enhances the strength, whiteness, and smooth finish of ceramic products, making it indispensable for premium-grade goods. - Paper Manufacturing:

The rising demand for high-quality paper in Egypt has increased the need for kaolin as a coating and filler agent, ensuring smooth texture and opacity in end products. - Paints and Coatings:

With Egypt’s booming construction and infrastructure sectors, the demand for paints and coatings is surging. Puresil India’s kaolin clay ensures optimal pigment dispersion, improved coverage, and cost-effectiveness for paint manufacturers. - Rubber and Plastics:

Kaolin clay enhances tensile strength and durability in rubber products, while in plastics, it acts as a cost-effective extender with excellent performance attributes.

Why Choose Puresil India for Kaolin Clay in Egypt?

As a leading supplier of industrial minerals globally, Puresil India is committed to delivering superior quality products and exceptional service. Here’s why we stand out:

- High-Quality Standards: Our kaolin clay undergoes stringent quality checks to meet international benchmarks.

- Customized Solutions: We offer grades tailored to specific industry needs, ensuring optimum performance in applications.

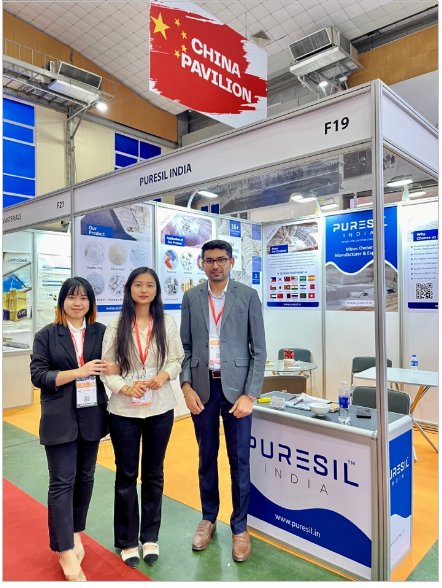

- Global Expertise with Local Focus: With a presence in over 20 countries, including expanding partnerships in Egypt, we understand market dynamics and cater to local demands efficiently.

- Sustainable Practices: Puresil India is dedicated to environmentally responsible mining and processing, ensuring a minimal ecological footprint.

Driving Growth Together

At Puresil India, we view our entry into the Egyptian market as a collaborative journey. By providing premium-grade kaolin clay, we aim to empower industries in Egypt, fostering growth, innovation, and sustainability.

We invite businesses in Egypt to partner with us for a brighter, more prosperous future. Let Puresil India be your trusted supplier for kaolin clay and other industrial minerals.

Contact us today to learn how we can support your industrial needs with unmatched quality and service.

About Puresil India

Puresil India is a global leader in supplying industrial minerals, including kaolin clay, quartz powder, feldspar, and silica sand. Renowned for our commitment to quality and innovation, we serve diverse industries such as ceramics, glass, paint, rubber, and paper. With a presence in over 20 countries, we are one of the fastest-growing export companies in the industry.